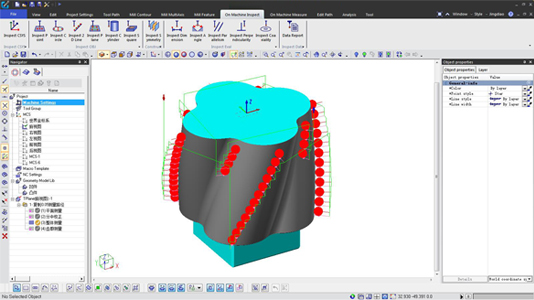

On-machine Measurement and Intelligent Modification Technology | Digitization of Machining and Continuous Production

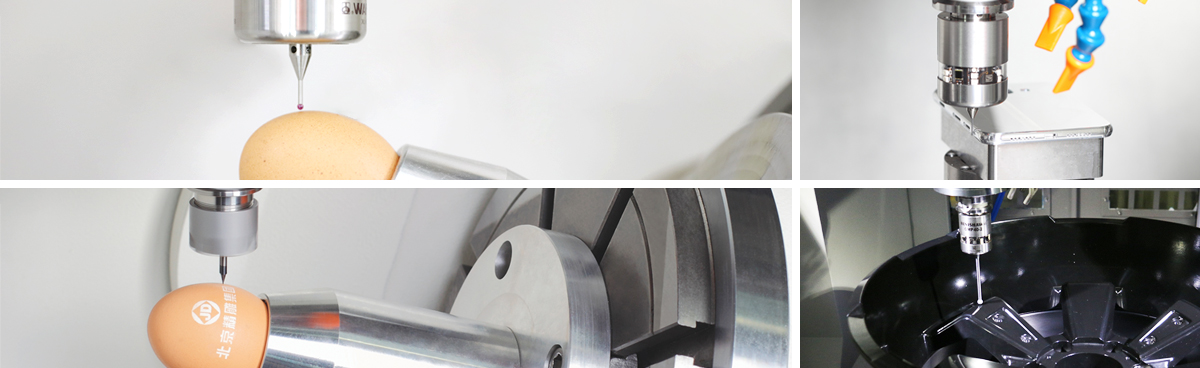

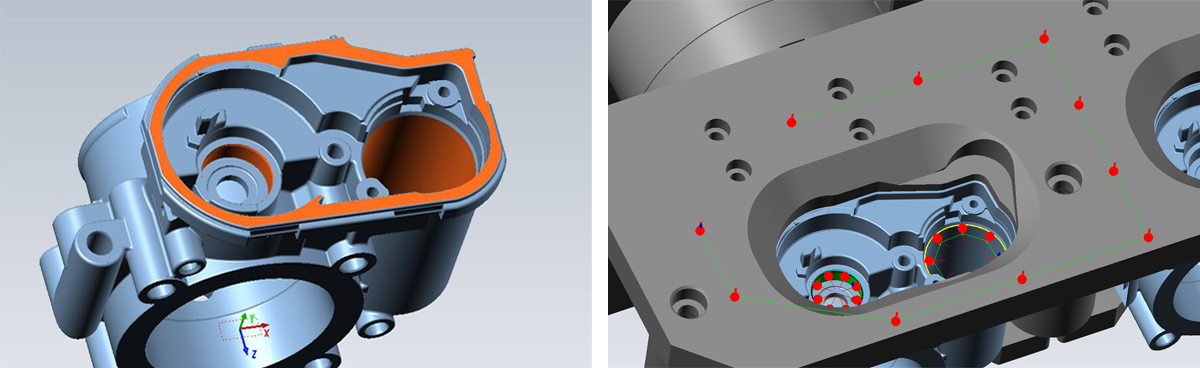

For parts quality control inspection is normally performed off machine which means interruption of production and instability considering manual operation.Jingdiao on-machine measurement and intelligent modification technology (OMIM) makes Jingdiao machine tools perceptive and smart based on our unique integration capability of CAD/CAM software and control system. With this technology, the operator, machine tool, process, and quality inspection, collaborates more effectively and achieve continuous production without any interruption.